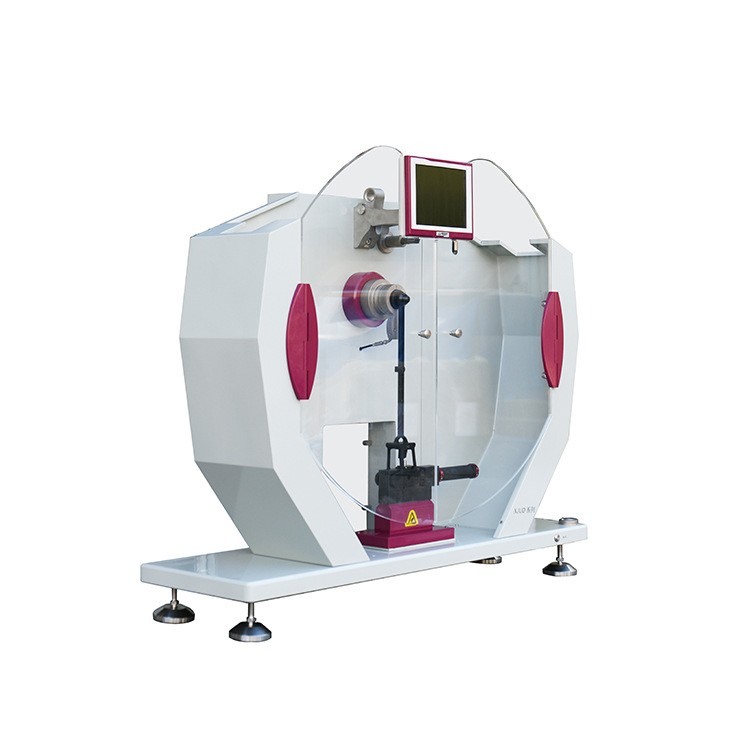

XGTW series rigid casing bending testing machine Jinjian JJ-TEST rigid casing bending testing machine

Hard casing bending test machine

It is suitable for bending test of insulating electrical casing and other materials. The total bending angle is 180º. After the test is completed, observe whether the sample has cracks. This testing machine complies with the requirements of GB/T 14823.2 "Special Requirements for Conduit for Electrical Installation - Flat Conduit of Rigid Insulating Material", JG/T3050 "Electrical Conduit and Fittings for Construction" and ZBG33008 "Polyvinyl Chloride Plastic Corrugated Electric Pipe". This testing machine can be used to test the three kinds of conduits specified in the standard at the same time, and it is not necessary to replace the forming die and the forming wheel. The operation is simple and convenient, and the use is safe and reliable.

technical parameter

Sample hard casing diameter: 16mm, 20mm, 25mm

Forming die groove bottom radius: 48mm, 60mm, 75mm

Wheel center track radius: 84mm, 105mm, 131.25mm

Forming die and wheel radius: 8.1mm, 10.1mm, 12.6mm

Wheel groove bottom diameter: 24mm, 30mm, 37.5mm

Total bending angle of specimen: 180º

Dimensions: length 350mm × width 320mm × height 850mm

Weight: 35kg

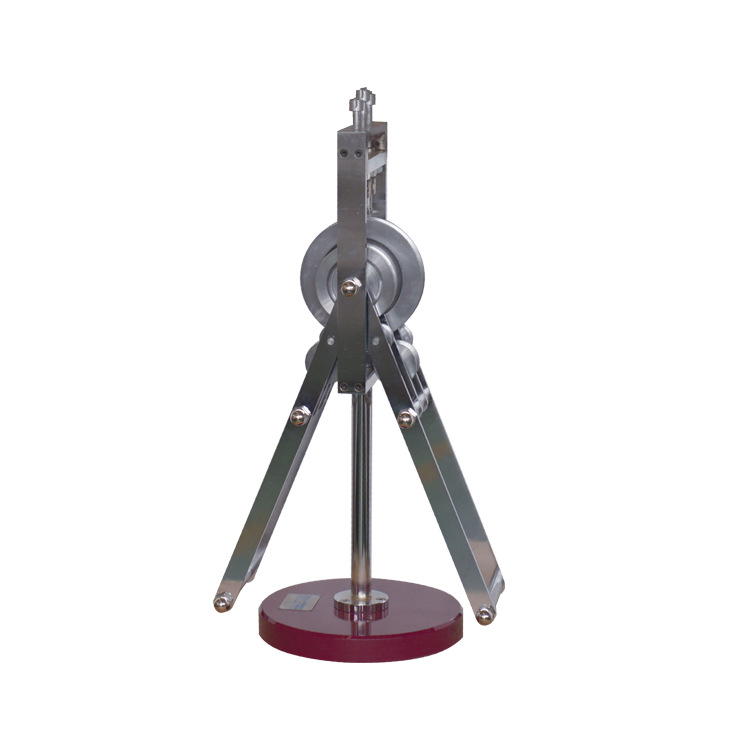

working principle

Cut samples of the same length according to the requirements, and check that the appearance of the samples is free from fractures, cracks and micro-holes directly visible to the human eye. Put the handle in the state of lifting up, select the corresponding groove shape, and insert the sample into the groove of the mold wheel. into the groove, and then depress the handle until the total angle of bending of the specimen is 180º. Then lift the handle, remove the casing and withdraw the spring, and check whether the spring and casing are damaged and whether the surface of the sample is broken or cracked.

Steps

1 Unpacking the instrument for inspection

2 The instrument should be placed on a firm and stable cement table.

3 operations

Prepare the preconditioned spring and casing, insert the spring into the casing.

According to the selected type wheel, loosen the corresponding T-bolts to the appropriate position (the distance between the arc plate and the type wheel is about 3mm), lift the two handles, and then pass the sample to be tested through the arc plate, Insert into the groove of the profile wheel, manually adjust the semi-circular groove of the pressure arc plate to tighten the T-bolt. Depress the handle until the total angle of bending of the specimen reaches 180º. The test is over. Lift the handle, loosen the T-bolt, remove the casing and withdraw the spring, check whether the spring and casing are damaged and whether there is any fracture or crack on the surface of the casing sample. is qualified.

Note: If three kinds of pipe diameters are made at the same time, the corresponding three T-bolts should be adjusted at the same time.

Chengde Jinjian Testing Co., Ltd.

- Phone: +86 15031678550-15031678550

- Business Type: Manufacturer

- Location: China

- Main Products: Moisture meter

- Total Employees:Less than 100 people

- Year Established:

- Export Markets:Asia,Europe,Africa

- Total Annual Revenue:

Recommended

-

XR-14 Latex High Speed Mechanical Stability Tester Jinjian JJ-TEST Latex High Speed Mechanical Stability TesterUSD 5000.00

XR-14 Latex High Speed Mechanical Stability Tester Jinjian JJ-TEST Latex High Speed Mechanical Stability TesterUSD 5000.00 -

XGTW series rigid casing bending testing machine Jinjian JJ-TEST rigid casing bending testing machineUSD 833.00

XGTW series rigid casing bending testing machine Jinjian JJ-TEST rigid casing bending testing machineUSD 833.00 -

XTC electrical casing impact testing machine Jinjian JJ-TEST testing machine Electric casing impact testing machineUSD 1333.00

XTC electrical casing impact testing machine Jinjian JJ-TEST testing machine Electric casing impact testing machineUSD 1333.00 -

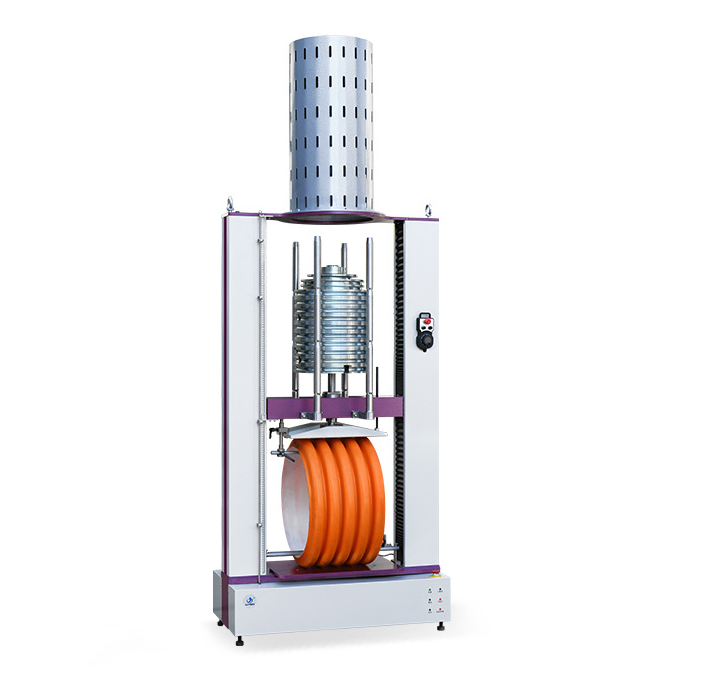

JJXGR dual-mode pipe creep ratio testing machine Jinjian JJ-TEST testing machine pipe creep ratioUSD 36666.00

JJXGR dual-mode pipe creep ratio testing machine Jinjian JJ-TEST testing machine pipe creep ratioUSD 36666.00 -

Mfi-1211 melt flow rate meter manual quality method Jinjian jj-test melt index meterUSD 2433.00

Mfi-1211 melt flow rate meter manual quality method Jinjian jj-test melt index meterUSD 2433.00